HP200 Multi-cylinder Hydraulic Cone Crusher: Powering Efficiency in Crushing Operations

Technical Specifications

Head diameter: 940 mm

Capacity: Up to 250 TPH

Power: 132 kW (200 HP)

Weight: 12,160 kg

The HP200 Multi-cylinder Hydraulic Cone Crusher is a high-performance crushing machine designed for demanding aggregate, mining, and quarrying applications. Combining advanced technology, robust engineering, and intelligent automation, HP200 Multi-cylinder Hydraulic Cone Crusher delivers superior productivity, reliability, and operational flexibility, making it a preferred choice for medium-to-fine crushing tasks.

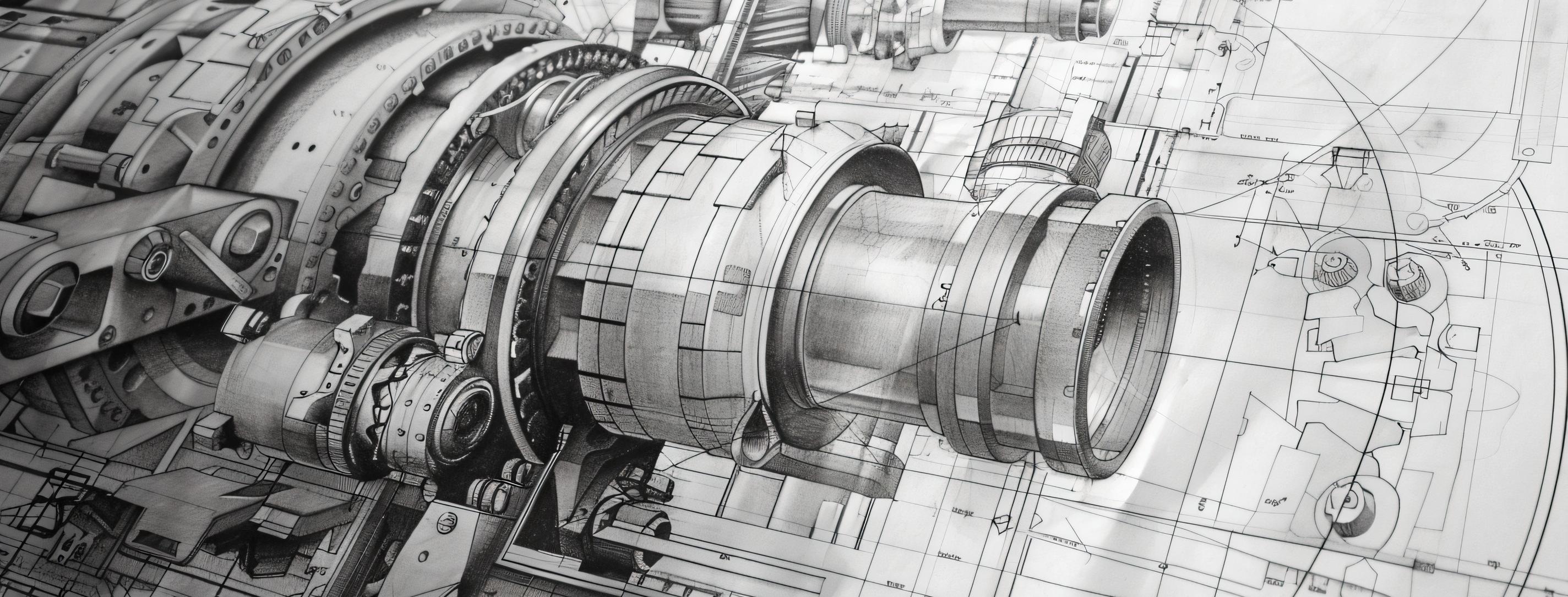

Advanced Hydraulic System

At the heart of the HP200 is its multi-cylinder hydraulic system, which enhances crushing efficiency and safety. Unlike traditional spring-based cone crushers, the hydraulic cylinders provide precise control over the cone crusher’s dynamic settings, enabling real-time adjustments to the discharge opening and compensation for wear. This ensures consistent product size and optimal throughput. The hydraulic system also offers automatic overload protection, safeguarding the cone crusher from uncrushable materials and minimizing downtime.

Intelligent Automation

Equipped with a state-of-the-art automation system, this type of Cone Crusher simplifies operation and maintenance. The integrated PLC (Programmable Logic Controller) allows operators to monitor and adjust parameters such as feed rate, power consumption, and cavity level in real time. This automation optimizes performance, reduces manual intervention, and enhances safety by providing alerts for abnormal conditions.

Versatile Crushing Capabilities

The HP200 Multi-cylinder Hydraulic Cone Crusher features a range of chamber configurations (coarse, medium, fine) to accommodate diverse material types and output requirements. With a maximum feed size of 210 mm and a capacity of up to 250 tons per hour (MTPH), it efficiently processes hard and abrasive materials, including granite, basalt, iron ore, and recycled concrete. Its high reduction ratio ensures superior particle shape, meeting strict specifications for construction and industrial applications.

Durable Design and Easy Maintenance

Constructed with premium wear-resistant materials, the HP200 Multi-cylinder Hydraulic Cone Crusher is built to withstand harsh operating conditions. Critical components, such as the mantle and concave, are replaceable, extending service life and reducing long-term costs. The HP200 Cone Crusher’s accessibility design allows for quick maintenance, with hydraulic adjustments and lubrication systems that minimize manual labor.

Eco-Friendly and Safe Operation

The HP200 Cone Crusher prioritizes environmental sustainability and operator safety. Advanced dust suppression systems reduce airborne particles, while noise-reducing components ensure compliance with workplace regulations. The hydraulic clearing function prevents material buildup, enhancing operational continuity.

Applications

Ideal for secondary and tertiary crushing stages, the HP200 Cone Crusher excels in mining, aggregates production, road construction, and recycling. Its compact design and compatibility with mobile or stationary setups make it adaptable to various production lines.

In summary, the HP200 Multi-cylinder Hydraulic Cone Crusher combines cutting-edge technology, versatility, and durability to deliver unmatched performance in modern crushing operations. Its intelligent design and user-friendly features ensure lower operating costs, higher uptime, and superior product quality, making it a strategic investment for industries requiring precision and efficiency.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/