The SP200 Multi-Cylinder Hydraulic Cone Crusher: A Revolution in Crushing Technology

The SP200 Multi-Cylinder Hydraulic Cone Crusher represents a significant advancement in crushing machinery, combining innovative engineering with cutting-edge technology to deliver exceptional performance in mining, quarrying, and aggregate production. Designed for high efficiency and durability, this crusher stands out for its robust construction, intelligent automation, and adaptability to diverse material processing requirements.

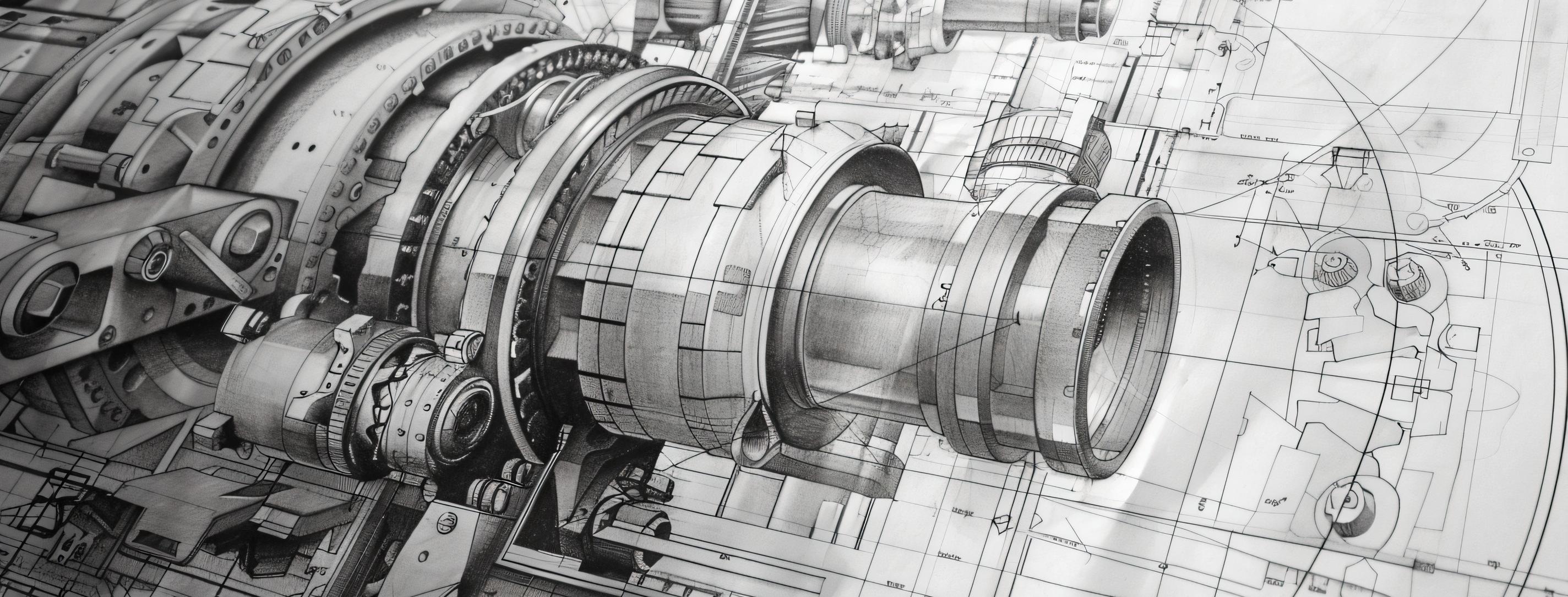

Advanced Hydraulic System

At the core of the SP200 cone crusher’s functionality is its multi-cylinder hydraulic system. Unlike traditional spring-based cone crushers, this system enables precise control over the crushing process. The hydraulic cylinders allow real-time adjustment of the discharge opening, ensuring optimal product size and consistent output quality. Additionally, the overload protection mechanism automatically releases foreign objects or uncrushable materials, minimizing downtime and preventing mechanical damage. This feature enhances operational safety and equipment longevity.

Superior Crushing Efficiency

The SP200 cone crusher is engineered for high productivity. The SP200 cone crusher's optimized crushing chamber design, combined with a high-speed rotating mantle, facilitates interparticle crushing, reducing energy consumption while maximizing output. The SP200 cone crusher’s ability to handle hard and abrasive materials, such as granite, basalt, and iron ore, makes it ideal for demanding applications. With a large processing capacity and fine-to-coarse crushing capabilities, the SP200 cone crusher ensures versatility across different stages of material reduction.

Intelligent Automation

Equipped with an advanced automation system, the SP200 cone crusher integrates sensors and programmable logic controllers (PLCs) to monitor operational parameters like pressure, temperature, and power consumption. Operators can adjust settings remotely, enabling real-time optimization of performance. This automation not only reduces manual intervention but also enhances precision, ensuring consistent product gradation and minimizing waste.

Durability and Maintenance

Constructed with high-strength alloys and wear-resistant components, the SP200 Multi-Cylinder Hydraulic Cone Crusher is built to withstand harsh operating conditions. Its modular design simplifies maintenance, allowing quick replacement of wear parts such as mantles and concaves. The accessibility of critical components reduces service time, boosting overall productivity.

Energy Efficiency and Environmental Compliance

The SP200 Multi-Cylinder Hydraulic Cone Crusher prioritizes sustainability. Its energy-efficient motor and hydraulic system lower power consumption, aligning with global environmental standards. Reduced noise and dust emissions further contribute to eco-friendly operations, making it suitable for urban and environmentally sensitive areas.

Conclusion

The SP200 Multi-Cylinder Hydraulic Cone Crusher is a game-changer in material processing, offering unmatched efficiency, reliability, and adaptability. Its combination of advanced hydraulics, automation, and durable design positions it as a preferred choice for industries seeking to optimize productivity while minimizing operational costs and environmental impact. For modern crushing operations, the SP200 sets a new benchmark in performance and innovation.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/